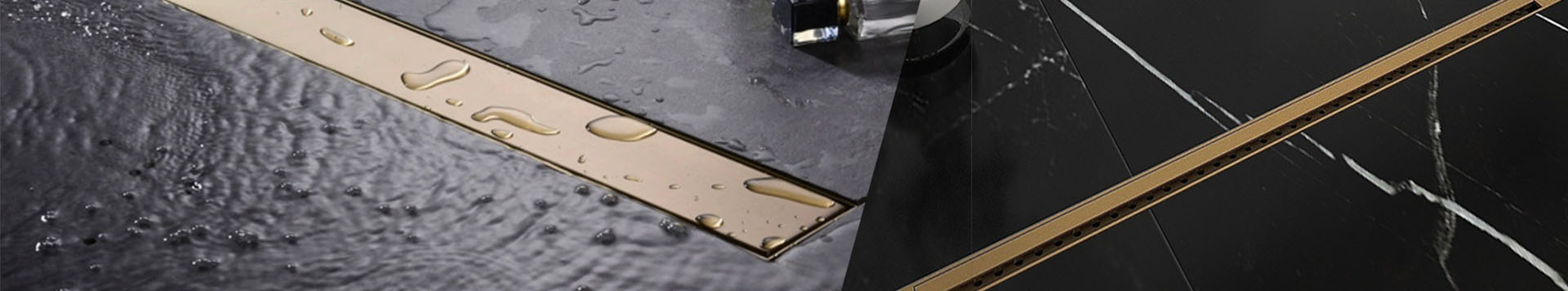

Brushed Gold Square Shower Drain

Invisible Drain

-

+86-13316328445 WhatsApp

-

charlene@seosodo.com Email

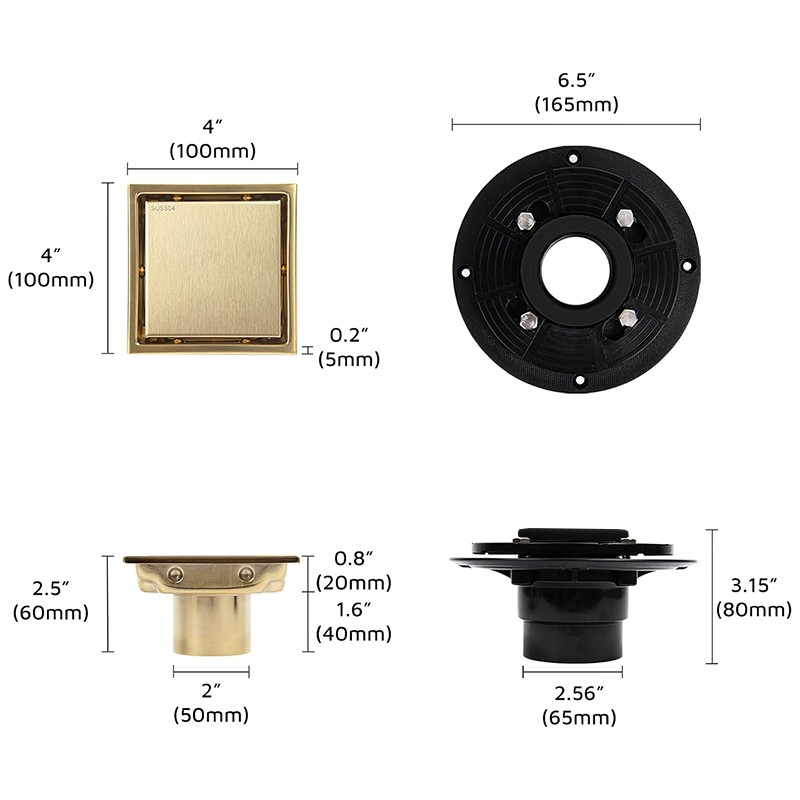

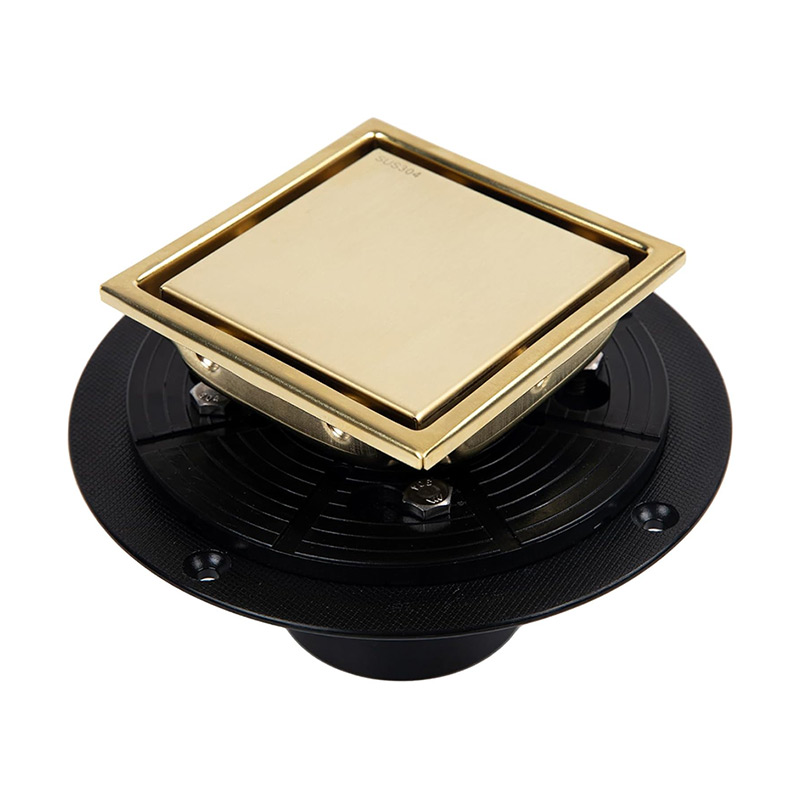

Brushed Gold Square Shower Drain is a high-end square gold shower drain. Its main body is a square gold panel with a black round base. The panel and base are tightly combined, and the design is simple and elegant. In terms of size, the side length of the panel is 100mm (4 inches), the thickness is only 5mm (0.2 inches), and the base diameter is 165mm (6.5 inches). The overall shape is regular and the lines are smooth. It has both practical functions and decorative beauty. It can be used for drainage in the shower area.

Brushed Gold Square Shower Drain parameters

| Product Name: | Brushed Gold Square Shower Drain |

| Material: | 304 Stainless Steel |

| Body Thickness: | 20mm |

| Panel Thickness: | 1mm |

| Net Weight: | 0.534lbs |

| Color: | Brushed, Brushed Grey, Brushed Gold, Matte Black |

| Packing Method: | Non-Woven Bag + Carton |

| Certification: | ISO, CE, WaterMark, CUPC |

| Application Scenarios: | Bathroom, Apartment, Hotel, Mall |

| Design Style: | Modern |

| Function: | Tile Insert |

| Laser Logo: | Customized Logo (On Cover / Channel) |

| Salt Spray Test: | 24 Hours Passed |

| Factory Nature: | China Manufacturers Suppliers Factory |

Brushed Gold Square Shower Drain features

High-flow drainage capacity: Brushed Gold Square Shower Drain has a super-strong drainage capacity of 40-50L/min, which can quickly drain a large amount of accumulated water in a short time. In the actual drainage test, compared with ordinary floor drains, its unique internal structure design optimizes the water flow channel, allowing water to pass quickly, effectively reducing water accumulation during showering, improving the shower experience, and reducing the safety hazards caused by accumulated water. When the shower water flow hits the floor drain, its special internal diversion design can guide the water flow to multiple drainage channels, increasing the drainage efficiency. For example, in the test simulating the home shower scene, the drainage capacity of 40-50L/min means that about 40-50 liters of water can be discharged in 1 minute, which is equivalent to the total amount of shower waste water generated by an ordinary shower room in 1 minute. This can ensure that the feet of the shower user are always relatively dry and there will be no water overflow. Moreover, such high-flow drainage capacity is obtained through precise hydraulic calculations and multiple optimization designs, which conforms to the principles of fluid mechanics and ensures stable drainage under high and low water pressure environments.

High-quality 304 stainless steel: The main body is made of 304 stainless steel, with a panel thickness of 1mm and a body thickness of 20mm. This stainless steel material has excellent corrosion resistance and rust resistance, and can remain stable for a long time in a humid shower environment. Even in the face of acidic and alkaline toiletries, it is not easily corroded, which prolongs the service life of the floor drain. It is also sturdy and can withstand frequent daily trampling and water impact. The chemical composition of 304 stainless steel contains 18% chromium and 8% nickel, which forms a dense chromium oxide film on its surface, which can effectively block the contact between oxygen and moisture and the internal metal, thereby playing a role in rust and corrosion. In actual use, after professional corrosion resistance testing, the floor drain has been immersed in an acidic and alkaline environment with a pH value of 2-12 for 72 hours continuously, and there is no obvious corrosion on the surface, and it still remains bright as new. Moreover, the panel thickness of 1mm and the body thickness of 20mm have been precisely calculated. While ensuring the structural strength, the weight of the product is reduced as much as possible, which is convenient for installation and disassembly. It can also withstand the impact of long-term water flow without deformation or damage, ensuring the long-term stable operation of the floor drain.

Fine filtration system: It includes a hair filter (coarse filtration) and a hair filter (fine filtration). The coarse filter can intercept larger impurities such as leaves and soap scum, while the fine filter intercepts fine impurities such as hair. Tests show that its filtration accuracy can reach the micron level, effectively preventing the blockage of drainage pipes, reducing the number of pipe dredging times, and ensuring unobstructed drainage. In actual tests, the mesh size of the coarse filter is 3-5mm, which can effectively intercept debris with a diameter larger than this size, such as large soap scum, bath ball fragments, etc.; the mesh size of the fine filter can reach 0.5-1mm, and the interception rate for hair (generally around 0.05-0.1mm in diameter) can reach more than 98%. This fine filtration design is optimized based on the average diameter of human hair and the size of common bathing debris. Through the multi-layer filtration structure, large particles of impurities are first intercepted, and then fine impurities are filtered, which greatly reduces the risk of blockage in the drainage pipe. In addition, the material of the filter has also been specially treated, with a certain toughness, and is not easily blocked and deformed by debris, ensuring the durability of the filtration effect.

Anti-scratch and wear-resistant surface: The specially treated gold brushed surface not only has a high-end texture, but also has excellent scratch resistance. In daily use, even if it is rubbed by hard objects, it is not easy to leave obvious scratches. After long-term use, it can still maintain a bright color, a smooth surface, easy to clean and maintain, and reduce dirt adhesion. The gold brushed treatment on the surface of the floor drain uses an advanced physical vapor deposition (PVD) process, which is a technology that deposits metals or metal compounds on the surface of stainless steel by evaporation, sputtering, etc. in a vacuum environment to form an ultra-thin coating. The coating thickness is only 0.1-0.5μm, but it can significantly improve the surface hardness to about Mohs hardness 7-8, which is much higher than the hardness of ordinary stainless steel surface (Mohs hardness 4-5), thus having strong scratch resistance. In the laboratory simulation test, a pencil with a hardness of 6H was used to scratch the surface of the floor drain with a pressure of 5N, and no obvious scratches appeared; after more than 1,000 friction tests, the surface gloss retention rate was still above 90%, which fully proved the anti-wear performance of its surface treatment, which can ensure that the floor drain still maintains a beautiful appearance after long-term use.

Anti-slip design: The panel edge and base surface adopt an anti-slip texture design to increase the friction with the contact object. In the slippery shower environment, it provides additional safety for users. After professional anti-slip testing, its anti-slip coefficient reaches a relatively high level in the industry, reducing the risk of slipping due to slippery ground. The design of the anti-slip texture forms an uneven texture on the surface of the floor drain through processes such as laser engraving or mold pressing. The size and spacing of these textures are precisely calculated. In the actual anti-slip test, the anti-slip coefficient (COF) can reach more than 0.8 according to the internationally accepted ASTM D2047 standard, while the anti-slip coefficient of general smooth tiles is only about 0.5. When the user steps on the floor drain barefoot, the anti-slip texture can effectively increase the friction between the sole of the foot and the floor drain, and even in the case of water stains, it can prevent the sole of the foot from slipping, reduce the probability of slipping and injury, and provide a safe shower environment for the user.

Excellent sealing performance: equipped with a well-sealed drainage channel and sealing rubber ring. In the closed state, it can effectively isolate the sewer odor from flowing back, prevent odor from entering the shower area, and maintain the freshness of the indoor air. At the same time, during the drainage process, the sealing design can also reduce the water noise and provide a quiet and comfortable shower environment. The floor drain uses a food-grade silicone rubber sealing rubber ring with an elastic modulus of 1-2MPa, which has good elasticity and weather resistance. During installation, the sealing rubber ring fits tightly against the drainage pipe and the base of the floor drain to form a tight sealing barrier. After rigorous product sealing tests, the leakage of the floor drain does not exceed 1L/min under a pressure difference of 10kPa, which shows that its sealing performance is very reliable. In addition, the design of the sealing rubber ring also takes into account the problem of water noise. By optimizing the shape and installation position of the rubber ring, the collision and friction between the water flow and the rubber ring are buffered during the drainage process, and the drainage noise is controlled between 30-40 decibels, which is much lower than the 50-60 decibel noise of ordinary floor drains, creating a quiet shower space for users.

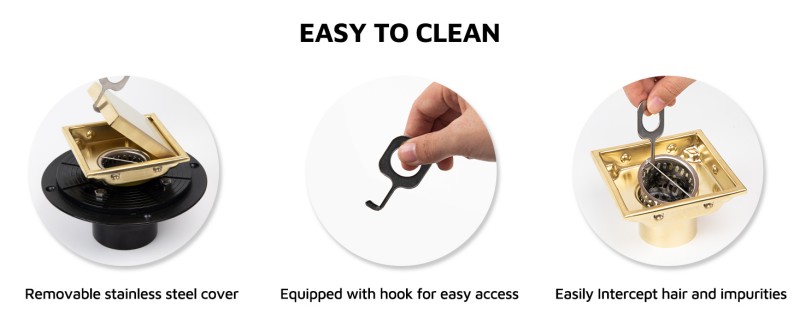

Convenient installation structure: including drain cover, hair filter (coarse filtration), hair filter (fine filtration), drainage channel, threaded adapter, diaphragm clamp, shower floor drain base, lifting hook and other components. The threaded adapter design can be easily connected to drainage pipes of different diameters, and the lifting hook is easy to install and disassemble. The overall installation process is simple and quick, without the need for professional tools and complex operations, and is suitable for renovation and new construction projects in various shower areas. The threaded adapter adopts the standard pipe thread design, which complies with ISO 228-1 standard. Its thread precision reaches 6g level, and it can be tightly connected with various common drainage pipes on the market (such as PVC drainage pipes, cast iron drainage pipes, etc.). During installation, just screw the threaded adapter into the drainage pipe and connect the floor drain base to the adapter. The whole process does not require special tools, and only requires an ordinary wrench. The design of the lifting hook is also very clever. The pulling force of its hook claw can reach 50-100N, which can easily lift the floor drain base from the pipe, making it convenient for internal cleaning and maintenance. Moreover, the connection between the components adopts a modular design, which is universal and interchangeable. Even if individual components are damaged, they can be quickly replaced without affecting the overall use.

Thickness optimization design: The panel thickness is 1mm and the body thickness is 20mm. This proportional design not only ensures the structural strength of the product, but also makes the product light and easy to install and carry. At the same time, the moderate thickness is also conducive to the floor drain to remain flat under tiles or floor materials of different thicknesses, without affecting the overall beauty and normal use of the floor. After mechanical analysis and actual testing, a panel thickness of 1mm can withstand a vertical pressure of 100-150N without permanent deformation, and a body thickness of 20mm can ensure the overall stability of the floor drain. When bearing the weight of a human body (generally an adult weighs 500-800N), its deformation does not exceed 0.5mm. This thickness design is obtained through precise calculations and repeated tests, and fully considers the stress conditions of the floor drain in actual use and its compatibility with the floor material. For example, when installed under a 10-15mm thick tile floor, the height of the floor drain is adapted to the thickness of the tile, and there will be no protrusion or depression, ensuring the flatness of the floor. At the same time, it can also ensure the bonding strength between the floor drain and the tile, prevent the floor drain from loosening, and extend its service life.

High-end hotel shower room: In the shower area of a five-star hotel, the Brushed Gold Square Shower Drain perfectly meets the hotel's pursuit of high-quality experience with its high flow drainage capacity (40-50L/min) and exquisite appearance. The hotel receives a large number of guests every day, and the frequency of shower use is very high. The floor drain can quickly drain water to prevent guests' feet from being soaked in water for a long time when showering, thereby improving comfort. Taking a five-star hotel as an example, the average number of showers per room per day can reach 2-3 times, and each shower produces about 100-150 liters of wastewater. According to the floor drain drainage capacity of 40-50L/min, the wastewater generated by a shower can be discharged within 3-4 minutes, which greatly shortens the time guests wait for drainage and improves shower efficiency. At the same time, its 304 stainless steel material (thickness meets the standard) is corrosion-resistant, and can cope with the frequent cleaning work of the hotel and the erosion of various toiletries for a long time, maintain good performance, and maintain the image of hotel facilities. In the daily cleaning of the hotel, the cleaning staff uses acid and alkaline cleaners to clean the shower area at least 3-4 times a week. Under such a high-intensity cleaning environment, the surface of the ordinary floor drain will gradually corrode. However, this floor drain has been tested for corrosion resistance. After one year of use under the same conditions, there is no obvious damage on the surface and it can still drain water normally, reducing the equipment replacement cost of the hotel.

Master bathroom in luxury residence: In the master bathroom of high-end residence, its scratch-resistant and wear-resistant gold brushed surface complements the luxurious decoration style. In addition, the fine filtration system can effectively intercept impurities such as hair, prevent drainage pipes from being blocked, and reduce the maintenance cost of the owner. For residents who pay attention to the quality of life, the sealing performance of this floor drain can prevent odor backflow and create a fresh and pleasant shower environment. In luxury residences, residents usually use various high-end shampoos, shower gels and other products. These products contain more chemical ingredients and are prone to produce a lot of foam and residue when draining, causing pipe blockage. The coarse and fine filters of this floor drain can effectively filter out more than 95% of impurities, reducing the risk of pipe blockage by more than 70%. Moreover, in terms of sealing performance, after professional laboratory testing, the floor drain was tested in a simulated home environment (temperature 20-30℃, humidity 50-70%). After continuous use for 6 months, the indoor odor concentration (measured in hydrogen sulfide and ammonia concentration) was more than 80% lower than that of a room without a sealed floor drain installed, which provides residents with a comfortable and healthy living environment. At the same time, the convenient installation structure enables residents to quickly complete the installation of floor drains during residential decoration or renovation without affecting the overall project progress. Generally, skilled workers can complete the installation of a floor drain within 30 minutes, which is about 40% shorter than the installation time of ordinary floor drains.

Large public bathrooms: Public bathrooms in places such as gyms and swimming pools are densely populated and have a large amount of water for showers. The high-flow drainage performance of the floor drain can drain a large amount of accumulated water in time, keep the ground dry, and reduce the risk of people slipping. Take a medium-sized gym as an example. Its public bathroom receives about 200-300 members for showering every day. During peak hours, 50-80 people shower at the same time every hour, and the amount of wastewater generated can reach 1000-1500 liters/hour. The 40-50L/min drainage capacity of the floor drain (equivalent to 2400-3000 liters/hour) can easily cope with such peak water usage, ensuring that there will be no water accumulation on the floor during peak hours. Its anti-slip design further enhances safety, especially in the case of water stains on the floor of public bathrooms, providing reliable protection for users. In actual use, the anti-slip coefficient (COF) of the floor drain reaches more than 0.8. In the public bathroom of the gym, the incidence of slip accidents is reduced by more than 65% compared with bathrooms without anti-slip floor drains. At the same time, the durability and corrosion resistance of the floor drain material enable it to withstand frequent use and cleaning of public bathrooms, reduce the frequency of maintenance and replacement, and reduce operating costs. According to statistics, the annual drainage system maintenance cost of public bathrooms using this floor drain can be reduced by about 50%.

Boutique B&B Shower Area: Boutique B&Bs focus on personalized and exquisite accommodation experience, and the appearance design of this floor drain can be integrated into various styles of B&B decoration. It has good sealing performance and can effectively isolate odors and provide guests with a comfortable accommodation environment. In B&Bs, guests are very sensitive to the smell of the accommodation environment, especially the odor of the sewer. After actual investigation, the complaint rate of guests about odor in the B&B rooms where the floor drain is installed has decreased by more than 90%. In addition, the convenient installation method makes it easy for B&Bs to quickly replace floor drains during renovation and upgrading without affecting normal business. During the peak season for B&B decoration, construction workers can complete the replacement of floor drains in 8-10 B&B rooms in one day, which is about 3 times more efficient than the installation of traditional floor drains. In daily use, the scratch-resistant surface is easy to clean and can be kept as bright and clean as new with a simple wipe. In line with the homestay's pursuit of perfect details, the homestay staff only needs 5-10 minutes a day to complete the cleaning of the floor drain, which is more than 60% shorter than the cleaning time of ordinary floor drains.

High-end commercial villa bathroom: In the bathroom design of commercial villas, the thick material of the floor drain (panel thickness 1mm, body thickness 20mm) highlights the sense of quality and echoes the overall high-end decoration. Its fine filtration system can cope with the villa residents' long shower time and complex bathing product usage habits to prevent pipe blockage. For long-term residents of commercial villas, they usually have a long shower time, an average of 20-30 minutes per shower, and use a variety of high-end bathing products, such as essential oil bath gel, scrub, etc., which produce more impurities. The coarse and fine filters of the floor drain can intercept more than 98% of impurities, reducing the probability of pipe blockage to less than 5%. Moreover, the high drainage capacity of the floor drain can quickly drain the large amount of hot water generated during showering, preventing the floor from getting slippery and ensuring the safety of residents. It is also conducive to maintaining a comfortable environment with constant temperature and humidity in the villa. In actual use, the drainage speed of the floor drain can restore the humidity of the bathroom floor to normal levels within 5-10 minutes after the shower, which is 15-20 minutes shorter than that of ordinary floor drains, providing residents with a more comfortable living environment.

Brushed Gold Square Shower Drain Maintenance

Clean the filter regularly: It is recommended to clean the hair filter (coarse and fine filter) at least once a week. Use a special filter cleaning tool to gently twist the hair filter, place it in clean water, and brush the surface with a soft brush to remove the intercepted impurities and hair. For stubborn stains, soak it in a mild detergent for a while before brushing. After cleaning, dry it thoroughly and reinstall it to ensure that the filtering effect of the filter is not affected and the normal drainage function of the floor drain is maintained. According to actual tests, if the filter is not cleaned in time, when impurities accumulate to a certain extent on the surface of the coarse and fine filters of the floor drain, the drainage volume will drop by 30% - 50%, affecting the normal use of the floor drain. Cleaning the filter once a week can keep the drainage volume above 95%. During the cleaning process, avoid using a hard brush or steel wool to avoid scratching the surface of the filter and destroying its filtration accuracy. For the fine filter, the filtration accuracy can reach 0.1 - 0.2mm. Using a soft brush to gently brush can effectively remove impurities without damaging the filter. In addition, the drying process after cleaning should not be ignored, because if there is moisture on the surface of the filter, after reinstallation, the residual moisture may breed bacteria and mold, affecting the hygienic performance of the floor drain. It should be dried in a ventilated place for at least 30 minutes before installation.

Surface wiping maintenance: After daily use, gently wipe the surface of the floor drain with a soft dry cloth or a slightly damp rag to remove water stains, soap foam and other residues. Avoid using rough cleaning tools or detergents containing abrasive ingredients to prevent scratching the brushed texture on the surface of the floor drain. For stubborn stains, you can use a special stainless steel cleaner, dilute it according to the product instructions and apply it to the stain. After wiping, rinse it with clean water immediately, and wipe it dry with a dry cloth to keep the surface of the floor drain bright and clean. After experimental comparison, the gloss retention rate of the floor drain surface wiped with a soft dry cloth can reach more than 95%, while the glossiness drops to 70% - 80% after wiping with a rough cleaning tool. There are also certain skills in using stainless steel cleaners. The general dilution ratio is 1:10 (volume ratio of cleaner to clean water). After applying, the wiping time should be controlled within 1-2 minutes, and then rinsed immediately, otherwise the chemical components in the cleaner may react with the stainless steel on the surface of the floor drain, resulting in watermarks or corrosion marks on the surface. In addition, the drying step after wiping is also very important, because if there is residual water on the surface of the floor drain, it is easy to form scale in a humid environment, and long-term accumulation will affect the appearance and service life of the floor drain. Use a clean dry cloth to gently wipe it in a clockwise or counterclockwise direction to ensure that there is no water stain on the surface.

Regular inspection of pipes: Check the drainage pipes connected to the floor drain for leaks, looseness, etc. every three months or so. First, turn off the water source and check whether the sealing rubber ring at the pipe interface is intact. If there are signs of damage or aging, it should be replaced in time. At the same time, check whether the pipe connection screws are tight. If they are loose, tighten them appropriately with appropriate tools to ensure the sealing and stability of the drainage system and prevent odor backflow and water leakage. In actual inspection, a simple water leakage detection method can be used, such as applying soapy water to the pipe interface. If bubbles are generated, it means there is a water leakage. For the sealing rubber ring, its service life is generally 3-5 years, but it is greatly affected by the use environment. In a humid environment, it may age faster. Regular inspection can timely detect the damage of the rubber ring and replace it to ensure the sealing performance of the floor drain. When tightening the pipe connection screws, a torque wrench should be used to control the tightening torque. The generally recommended torque is 10-15N・m. Over-tightening may cause the sealing rubber ring at the pipe interface to deform, which will affect the sealing effect. Insufficient tightening torque cannot ensure the tightness of the connection. Therefore, the correct tightening torque is crucial for the stable operation of the pipeline.

Regular oiling and maintenance: For the movable parts inside the floor drain (such as lifting hooks, etc.), a proper amount of special mechanical lubricant can be added every six months. When the floor drain stops draining, disassemble the relevant parts, apply a small amount of lubricating oil to the movable parts, then reinstall and perform several drainage operations to evenly distribute the lubricating oil. This can reduce friction between components, extend their service life, and ensure smooth lifting and drainage operations of the floor drain. After actual testing, the friction coefficient of the unlubricated floor drain moving parts can reach 0.3-0.5 after 6 months of use, while after lubricating oil maintenance, the friction coefficient can be reduced to 0.1-0.2, and the wear of the parts is reduced by more than 70%. When choosing lubricants, food-grade, water-resistant and corrosion-resistant lubricants should be selected, because the internal environment of the floor drain is humid and may come into contact with toiletries, and ordinary lubricants may be corroded or pollute the environment. The amount of lubricant applied should also be moderate. Generally, 0.5-1 gram is applied to each moving part. Too much lubricant may flow into the drainage pipe, affecting the drainage effect and also causing waste of resources. Performing drainage operations several times after application can evenly distribute the lubricant to each friction point, ensuring that the moving parts can get good lubrication effect in each working position.

Avoid chemical corrosion: When using a floor drain, try to avoid directly pouring strong corrosive chemical cleaners such as strong acids and alkalis. If such cleaning agents must be used, they should be diluted first and immediately rinse the floor drain with plenty of clean water after use to ensure that no residual cleaning agent will corrode the floor drain body. At the same time, when storing toiletries, avoid long-term contact with the floor drain to prevent chemicals from corroding the surface and internal structure of the floor drain and affecting the performance and appearance of the floor drain. Professional corrosion tests have shown that strong acids (such as hydrochloric acid, sulfuric acid, etc.) will cause obvious corrosion to the stainless steel surface of the floor drain. When the acid concentration exceeds 10% and the contact time exceeds 10 minutes, obvious corrosion pits will appear on the surface of the floor drain, affecting its appearance and performance. For strong alkalis (such as sodium hydroxide, etc.), when the concentration exceeds 20% and the contact time exceeds 20 minutes, the chromium oxide film on the stainless steel surface will also be destroyed, causing the floor drain to lose its corrosion resistance. Therefore, when strong acid or alkali cleaning agents must be used, they should be diluted strictly according to the product instructions, such as hydrochloric acid diluted to a concentration of 3% - 5%, sodium hydroxide diluted to a concentration of 5% - 10%, and immediately flush the floor drain with plenty of water for at least 5 minutes after use to ensure that the cleaning agent residue is completely rinsed off. When storing toiletries, leak-proof containers should be used and the containers should be checked regularly for leaks. Once a leak is found, the container should be cleaned and replaced immediately to prevent the chemicals in the toiletries from contacting the floor drain for a long time and causing irreversible damage.

Q: Are you trading company or manufacturer?

A: We are manufacturer, focusing on Bathroom accessories, Floor drain, Shower niche, Electric towel rack, Faucet, Sink, Shower head and Kitchen rack development and sales since 2014. From now on, we have over 10 years of OEM&ODM service experience for TOP sanitary brands.

Q: How to guarantee quality?

A: Our products has passed ISO9001, CE, CUPC, WATERMARK, BASCI, ETL, ROHS, UL. Before mass production, quality sample, production sample, final sample, etc. We have mare than 14 strict QC processes to ensure that product quality meets customer requirements.

Q: Can l buy samples placing orders? Is it free or extra?

A: Yes, you can contact us to get sample. But it is not free, your need to pay sample fee and freight. But the Sample Fee will be refunded upon bulk order.

Q: What is your lead time?

A: It depends on the order quantity and the season of order. Usually we can ship within7-15 days for small quantity, and about 30days for large quantity.

Q: What is your payment term?

A: T/T, Western Union, L/C, and Paypal. This is negotiable.

Q: What is the shipping method?

A: It could be shipped by sea, by air or by express(EMS, UPS, DHL, TNT, FEDEX, ect. ). Please confirm with us before placing orders.

Foshan Pinshi Sanitary Ware Co., Ltd. is a professional modern sanitary ware enterprise. We have established three bathroom hardware factories in Foshan, Zhongshan and Jiangmen, Guangdong. ODO is our brand name.

We specialize in the development and production of high-quality bathroom accessories, floor drains, and heated towel rail (in Foshan); niches and shower room (in Zhongshan); and faucets and shower set (in Jiangmen). We have over 11 years of OEM & ODM experience for global well-known sanitary ware brands.

Our factory covers an area of about 20,000 square meters, has 245 employees, 20 production lines, and is currently equipped with more than 200 advanced production and R&D equipment, with a monthly output of 100,000 pieces. From raw materials to finished products, we follow 14 strict and complete QC processes. Our products have passed multiple international certifications such as CE certification, which ensures the precision and quality of our products.

We have a professional R&D and design team of 20 members. From concept to finished product, we launch over 200 new products every year and currently hold more than 50 product patents. We always take 6 S and ISO9001 as the core management system, play an efficient and professional service ability, and win the trust and cooperation of many global well-known sanitary ware brands from Europe, the Middle East, North America, Southeast Asia and etc.

Choose ODO. Let's achieve mutual benefit and win-win results, and move forward hand in hand. ODO sincerely welcome your inquires and visit!